Sviluppiamo e progettiamo ogni parte delle nostre macchine per raggiungere ogni obiettivo

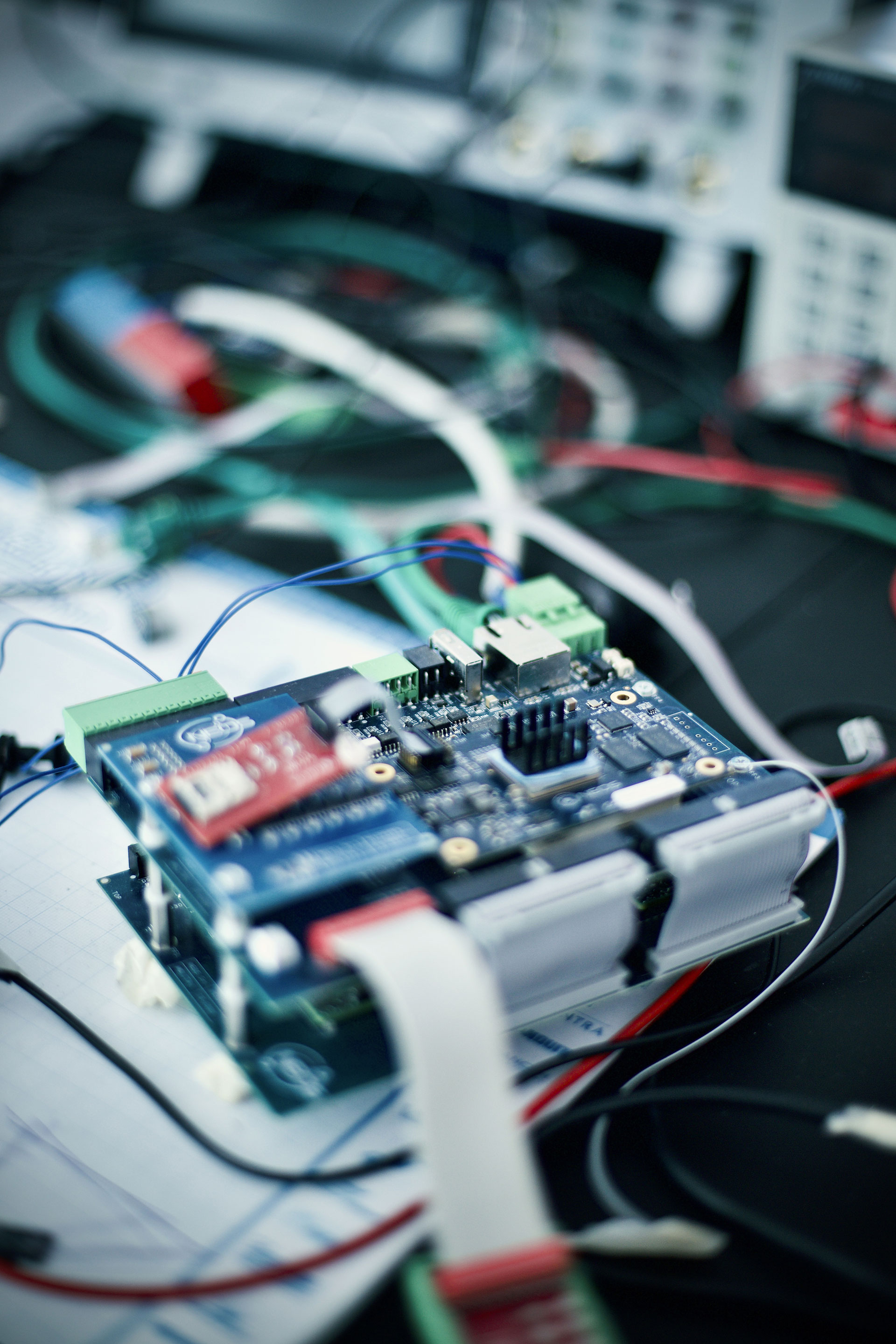

Sviluppo Elettronica

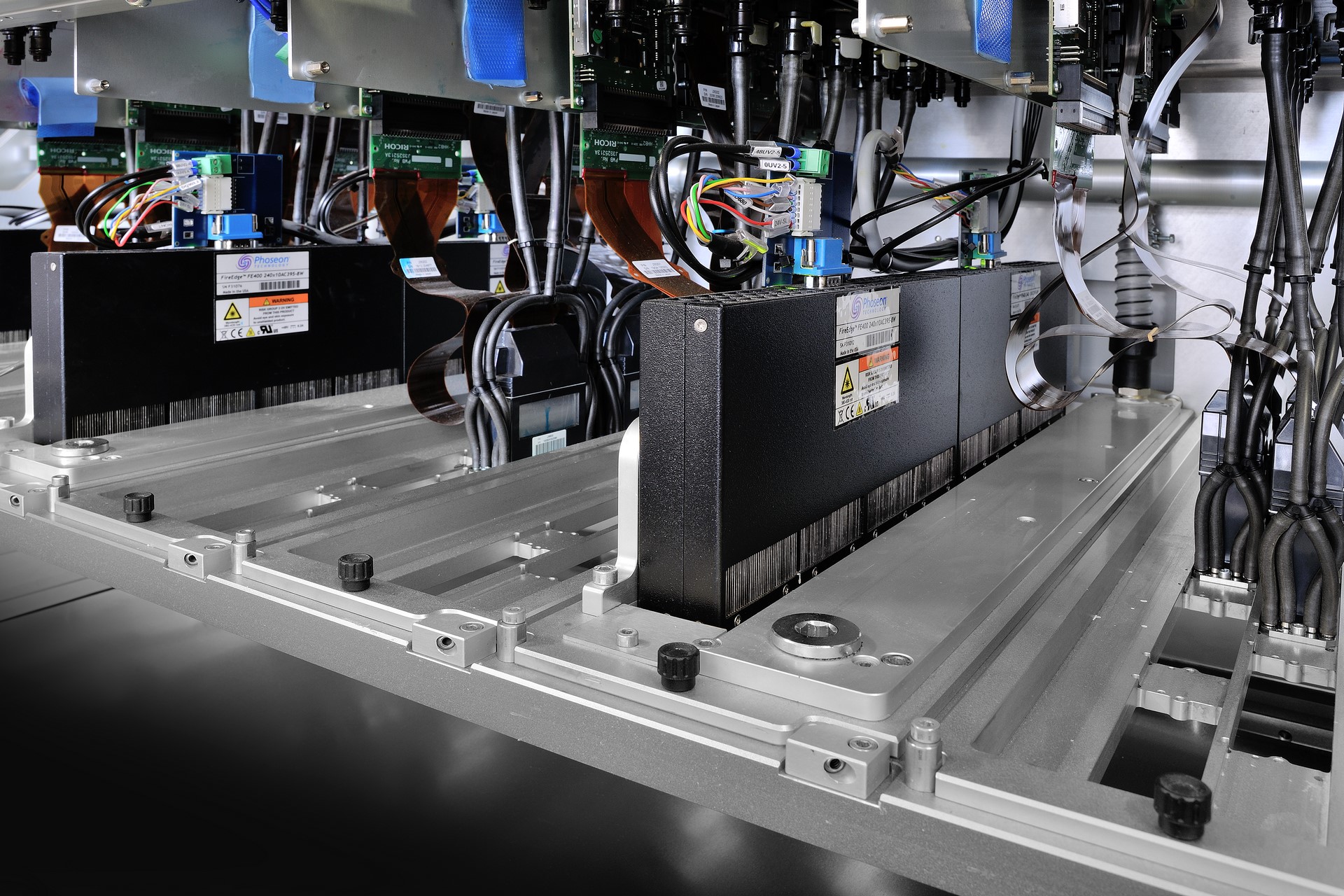

I sistemi di stampa moderni richiedono un grande sviluppo dal punto di vista tecnologico.

Ogni PrintHead ha particolari requisiti elettrici ed ha una modalità di gestione propria.

La generazione dei segnali elettrici in grado di pilotare le PrintHeads è di importanza critica, in quanto determina la quantità di colore espulsa dalle PrintHeads.

La sincronizzazione e l’allineamento dei segnali di pilotaggio è sempre più ardua in quanto le velocità di stampa sono sempre maggiori. Al fine di ricavare la massima qualità ed efficienza dai nostri impianti, l'elettronica vieni totalmente progettata e realizzata internamente all'azienda. Questo rispecchia pienamente la visione con cui Neos si approccia al mercato, ricerca e innovazione sono i due concetti cardine su cui si fonda Neos.

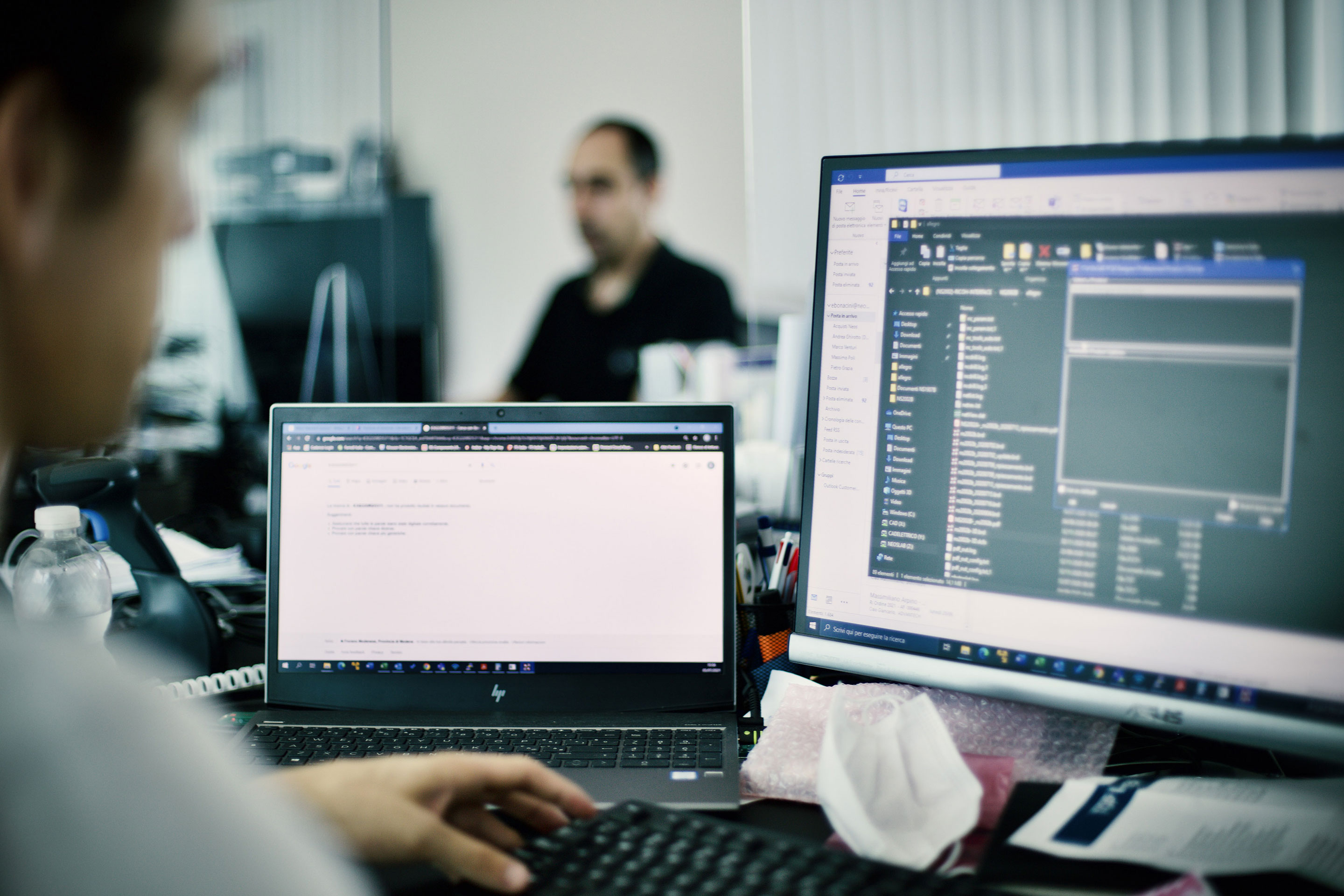

Sviluppo software

I sistemi di stampa Neos si avvalgono di un software macchina proprietario interamente sviluppato internamente a Neos.

L'interfaccia operativa è completamente integrata col sistema di stampa ed è personalizzabile per assecondare le richieste del cliente.

Il software gestisce l'intero processo di stampa, partendo dal file grafico e concludendo con la gestione della testa di stampa.

Le macchine Neos supportano diverse marche e modelli di PrintHeads per adattarsi al meglio alle esigenze applicative.

Grazie al software Neos la macchina è completamente integrabile coi più noti sistemi di Color Management Industriali.

Il software permette inoltre di esporre i dati, tramite diversi protocolli, verso sistemi di terze parti, per integrazione col resto dei sistemi industriali.

Color Management

Un sistema di gestione del colore (chiamato CMS, Color Management System) è un insieme di strumenti software creati per garantire uniformità di cromia tra i diversi dispositivi, indipendentemente dal supporto o dal dispositivo stesso utilizzato per la stampa. Poiché il colore dipende dai dispositivi e poiché i diversi dispositivi utilizzano diverse tecnologie per produrre i colori, la coerenza dei colori tra i supporti è una grande sfida. I sistemi di gestione del colore sono indispensabili nei processi di stampa, in quanto permettono di comprendere l’andamento della qualità di uno prodotto e, con tools di controllo dedicati, consentono di creare le condizioni ideali per ottenere la migliore qualità di stampa possibile, riducendo tempi e scarti in produzione, oltre a raggiungere standard qualitativi elevati. NEOS si avvale di personale specializzato e software dedicati per la messa a punto dei propri sistemi di stampa digitale, creando e utilizzando gli strumenti necessari per una corretta applicazione del Color Management.

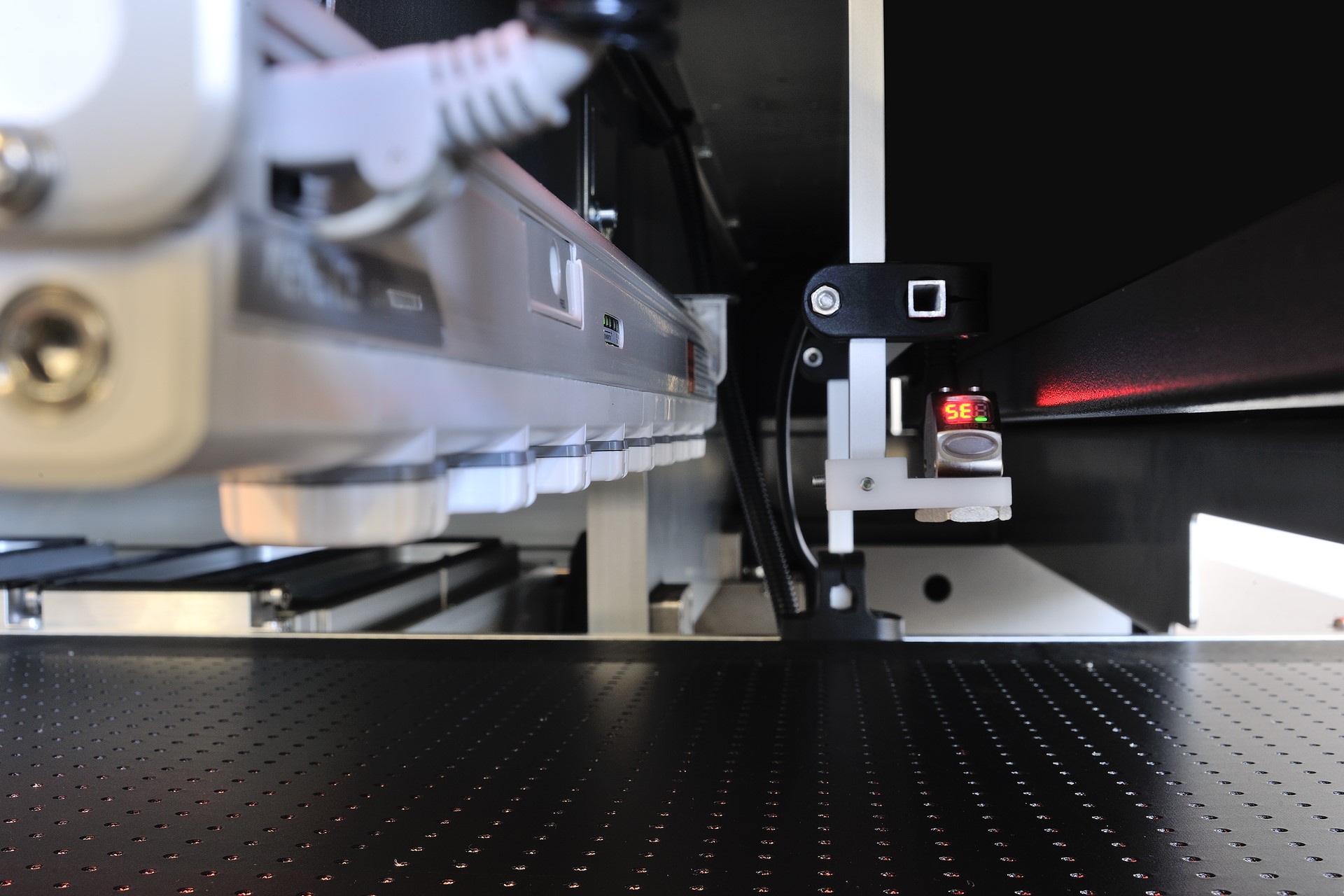

Vision System Technology

Uno degli ultimi traguardi di Neos è stato lo sviluppo di un sistema di visione ad alta definizione. Tale sistema è progettabile solo unendo teoria ed esperienza, nel nostro caso programmazione software (deep learning) ed esperienza di stampa digitale.

Si tratta di un modulo installabile su tutte le macchine da stampa Neos. Ciò che lo differenzia dagli altri sistemi commerciale è l'elevatissima risoluzione unita ad un vasto fronte stampa.

La combinazione di questi due fattori genera uno strumento estremamente versatile, utilizzabile dalla fase di messa a punto fino al processo finale di stampa.

Printing Process Optimiztion

La stampa digitale richiede un insieme di elementi e di lavorazioni affinchè un prodotto stampato possa essere finito e immesso nel mercato.

Si crea quindi un processo nel quale l’ottimizzazione dei suoi parametri, può determinare numerosi vantaggi sia da un punto di vista qualitativo che economico.

NEOS si avvale di personale qualificato e di partner specializzati in grado di valutare, elaborare e creare le soluzioni più adatte a definire un processo produttivo dedicato alle esigenze del cliente.

Meccanica di Precisione

Utilizzo della modellazione tridimensionale per il dimensionamento delle varie componenti.

Utilizzo di tecnologie costruttive dalle più classiche di carpenteria fino a lavorazioni di precisione micrometriche.

Calcolo strutturale, dinamico, fluidodinamico e termico.

Le varie aree sono indirizzate all'ottenimento di allineamenti, posizionamenti, linearità di moto e approvvigionamento di fluido alle testine per il raggiungimento della migliore qualità di stampa.

R & D Department

"La vita è come andare in bicicletta. Per mantenere l’equilibrio devi muoverti" (Albert Einstein).

Il movimento, e dunque l'innovazione, è la base su cui è stata fondata Neos. Neos crede fermamente nell'innovazione e pertanto compie ingenti investimenti sulla ricerca: la sezione di ricerca e sviluppo è tecnologicamente all'avanguardia, tramite un team che fonde metodo ed esperienza si pone l'obbiettivo di aumentare l'efficacia dei propri sistemi.

Le moderne stampanti digitali richiedono un ingente processo di studio al fine di aumentare la qualità di stampa, ogni stampante richiede un accurato processo di messa a punto.

Viene infatti studiata la fisionomia di ogni singola PrintHead, al fine di ottimizzare e raffinare il getto di inchiostro per ottenere una stampa conforme alle richieste del cliente.